Recently, Prof. Zhang Min and Huang Weihong, the corresponding author and the first author of our research group, published the research results entitled “ultra high drivability, high mobility, low voltage and high integration internally stretchable transistors” on Nanoscale.

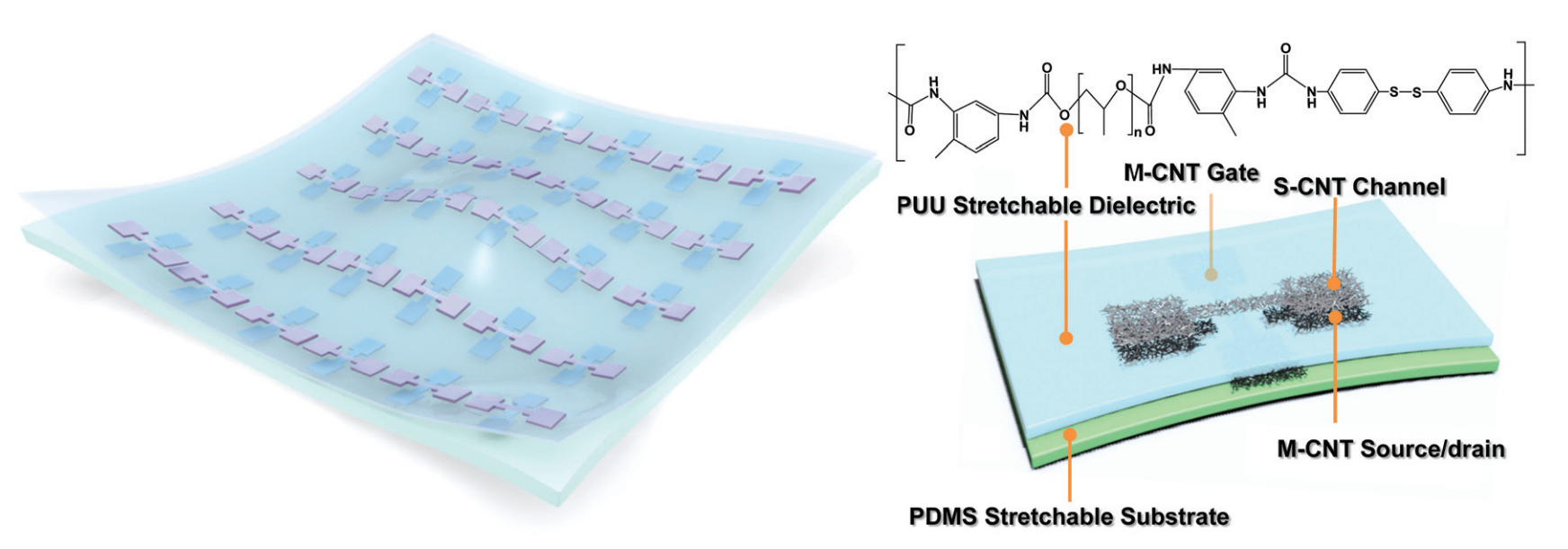

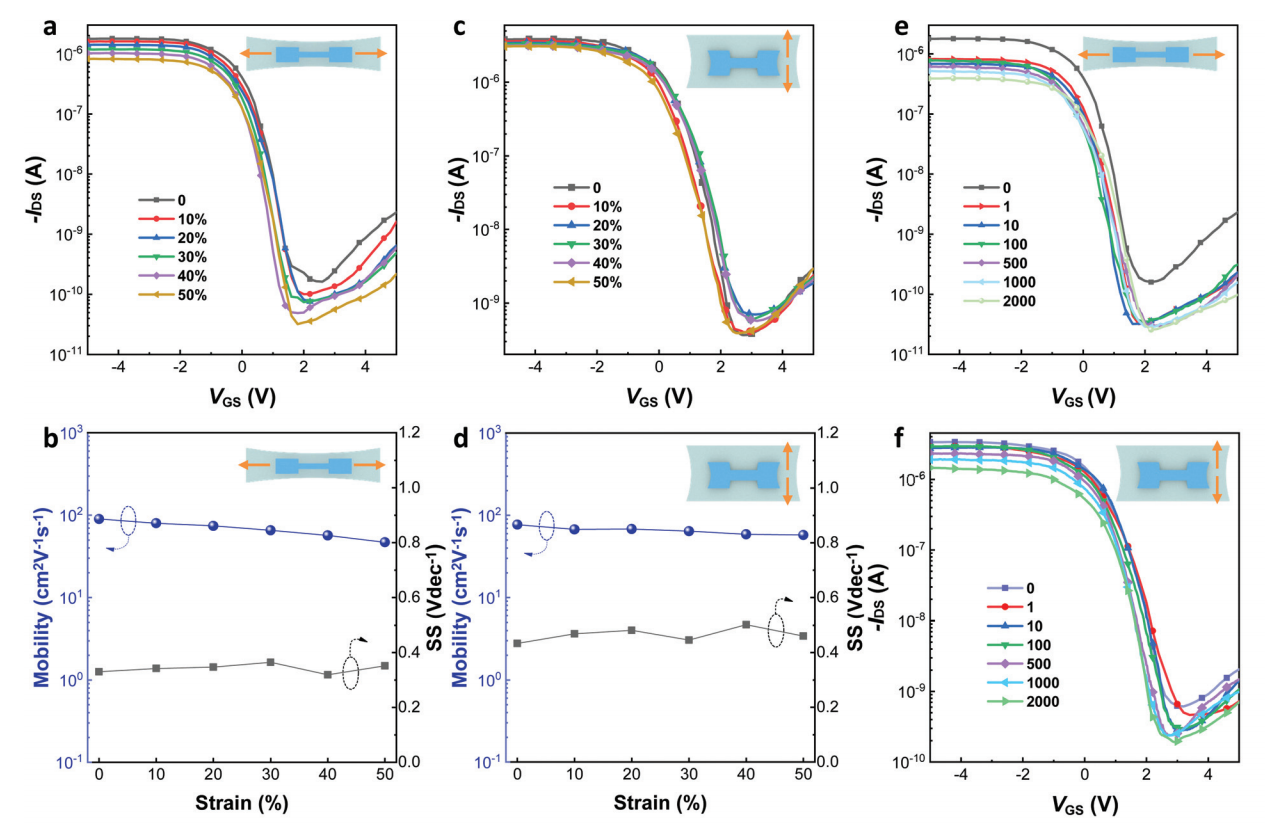

Realizing intrinsically stretchable transistors with high current drivability, high mobility, small feature size, low power and the potential for mass production is essential for advancing stretchable electronics a critical step forward. However, it is challenging to realize these requirements simultaneously due to the limitations of the existing fabrication technologies when integrating intrinsically stretchable materials into transistors. Here, we propose a removal-transfer-photolithography method (RTPM), combined with adopting poly(urea-urethane) (PUU) as a dielectric, to realize integratable intrinsically stretchable carbon nanotube thin-film transistors (IIS-CNT-TFTs). The realized IIS-CNT-TFTs achieve excellent electrical and mechanical properties simultaneously, showing high field-effect-mobility up to 221 cm2V−1s−1and high current density up to 810 μA mm−1at a low driving voltage of −1 V, which are both the highest values for intrinsically stretchable transistors today to the best of our knowledge. At the same time, the transistors can survive 2000 cycles of repeated stretching by 50%, indicating their promising applicability to stretchable circuits, displays, and wearable electronics. The achieved intrinsically stretchable thin-film transistors show higher electrical performance, higher stretching durability, and smaller feature size simultaneously compared with the state-of-the-art works, providing a novel solution to integratable intrinsically stretchable electronics. Besides, the proposed RTPM involves adopting removable sacrificial layers to protect the PDMS substrate and PUU dielectric during the photolithography and patterning steps, and finally removing the sacrificial layers to improve the electrical and mechanical performance. This method is generally applicable to further enhance the performance of the existing transistors and devices with a similar structure in soft electronics.

In conclusion, we have proposed a scheme that enables intrinsically stretchable transistor fabrication compatible with advanced photolithography fabrication technology, making the integration and mass production of IISTs possible. Combining the intrinsically stretchable high-k PUU elastomer dielectric, high mobility semiconducting CNTs and the novel removal-transfer-photolithography fabrication method, the realized IIS-CNT-TFTs exhibit outstanding electrical properties compared with the existing milestone works. These transistors present high current density and high mobility up to 810 μA mm−1and 221 cm2V−1s−1, respectively. Besides, the transistors possess a static power consumption as low as 490 fW at VDS= −10 mV, a small feature size as small as 20 μm width and 10 μm length when Ion/Ioff> 103, and high integration capability, which are suitable for advanced stretchable electronic applications. Moreover, the transistors show excellent tensile stability and retain high electrical performance at strains biaxially as high as 50%, presenting promising application potential for deformable soft electronic systems. The transistors can survive as large number as 2000 stretching cycles, and the mobility is kept over 50% of that after first stretching. This work is of great significance for the realization of high-performance intrinsically stretchable electronics.