1. Research and application of carbon based devices

1.1 Controlled repetitive growth of carbon nanotubes

|

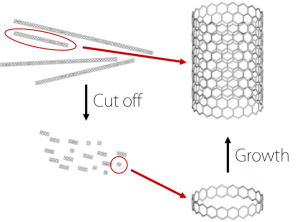

Realizing in situ growth of single-walled carbon nanotubes by PECVD using methane as carbon source on silicon wafer with iron-based catalyst. Firstly, adjusting the fabrication conditions of the catalyst, such as the ratio, temperature, mixing time, etc., and transferring the catalyst dispersion to the substrate by drop coating, spin coating and other processes. And then adjusting the parameters of PECVD equipment to realize the in-situ growth of carbon nanotubes. The CNTs were dispersed into a strong acid / strong oxidation dispersion system, and the CNTs were broken into “seeds” by high temperature, ultrasound and other methods. On this basis, the “seeds” was transferred to silicon or quartz and it will continue to grow. Theoretically, the grown carbon should have the same diameter and chirality as the previous CNT, and that method will improve the homogeneity of the devices.

1.2 Research on the conductivity of carbon nanotubes network structure

|

|

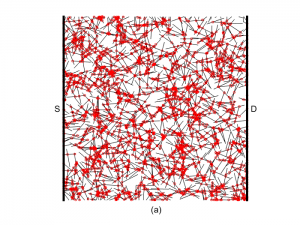

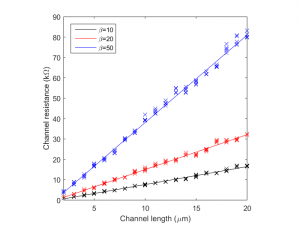

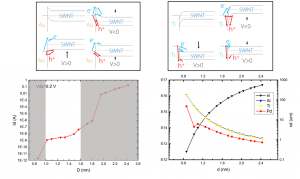

On the one hand, the distribution of carbon nanotubes in the channel is theoretically modeled, and the relationship between the relevant geometric factors in the carbon nanotubes network is obtained by integrating the probability distribution. On the other hand, Monte Carlo method is used to simulate the structure of carbon nanotube network, analyze the macro electrical characteristics of the whole network under the influence of different channel length, density, carbon tube length and other factors, and compare with the analytical expression obtained by theoretical analysis. The theoretical method developed by us and Monte Carlo simulation method can be effectively applied to the study of the conduction mechanism of the channel network structure in CNT-TFT.

1.3 Controllable growth of carbon nanotubes diameter and density by using silica spheres

|

|

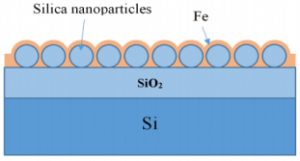

The irregular substrate surface on the nanometer scale was obtained by coating the silica spheres on the substrate. On this basis, the diameter distribution of carbon nanotubes can be controlled by PECVD. And the overall density of carbon nanotubes was improved.

1.4 Simulation of carbon nanotubes / metal contact

|

Explore the effect of carbon nanotubes chirality and metal work function on contact resistance. The matching relationship between the diameter of carbon nanotubes and the work function of metals is given by the relationship between the chirality of carbon nanotubes and the characteristics of semiconductor materials such as the forbidden band width and semiconductor properties. Due to the low carrier concentration of the carbon nanotube material itself, especially when the work function does not match, a large Schottky barrier is easy to form, but this effect can be largely eliminated after the process conditions such as annealing in the experiment. This phenomenon is to discuss the electron transport mechanism of metal-carbon nanotube heterojunctions.